Aeriform is a versatile product with a shape that can fit into any kind of environment. It is available in different colours and finishings in line with its brand identity. The color palette takes inspiration from the multiple shades of air and they are provided with both matte or shiny finishing.

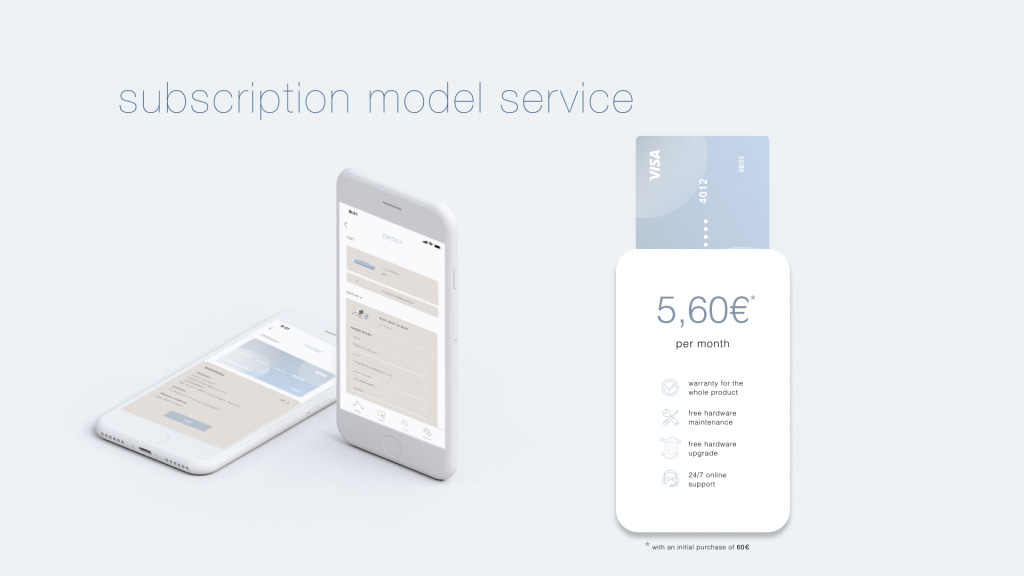

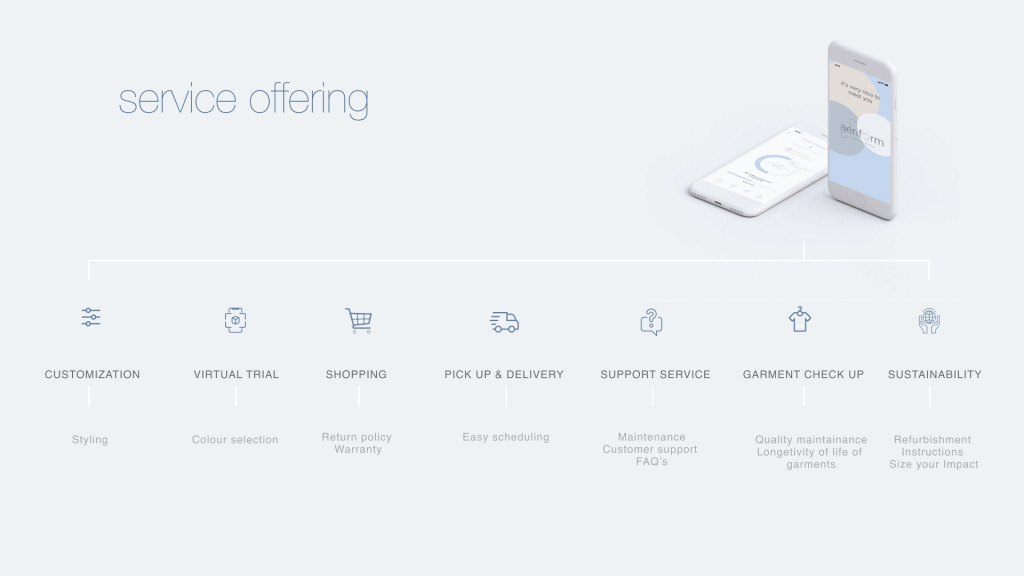

Aeriform’s service is subscription based. With an initial purchase of 60 euros the customer buys the product, by paying a monthly fee the user can lease the hardware with all the components that are needed to make Aeriform work. This kind of subscription model on the one hand ensures a continuous income for the start-up and on the other hand guarantees maintenance and support to the users during the whole product lifecycle. Additionally it also minimises electronic waste and ensures a circular lifecycle of the hardware. Refer to the project book to view the service blueprint, BMC, offering map, customer journey and system map.

Aeriform is delivered in a box designed to be useful during the installation phase. Inside the packaging the user will find the assembled product, the wall attachment bar and a small box containing the screws and fishers necessary to hang the product on the wall. On the inner side of the package the instructions to install Aeriform are printed. This allows to minimise paper waste and fully exploit the box. The packaging, once opened, guides the user to which height they accurately can install the product.

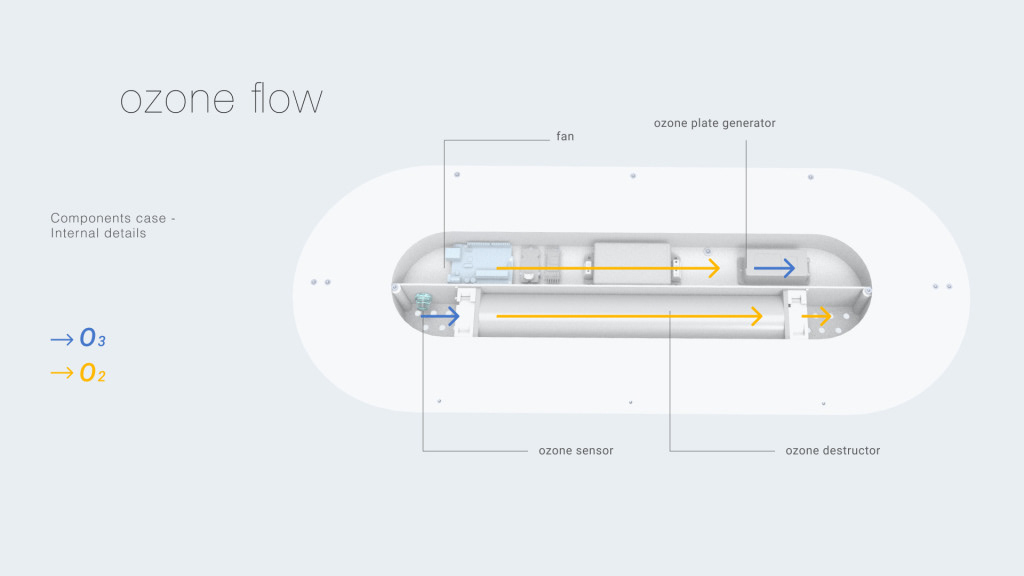

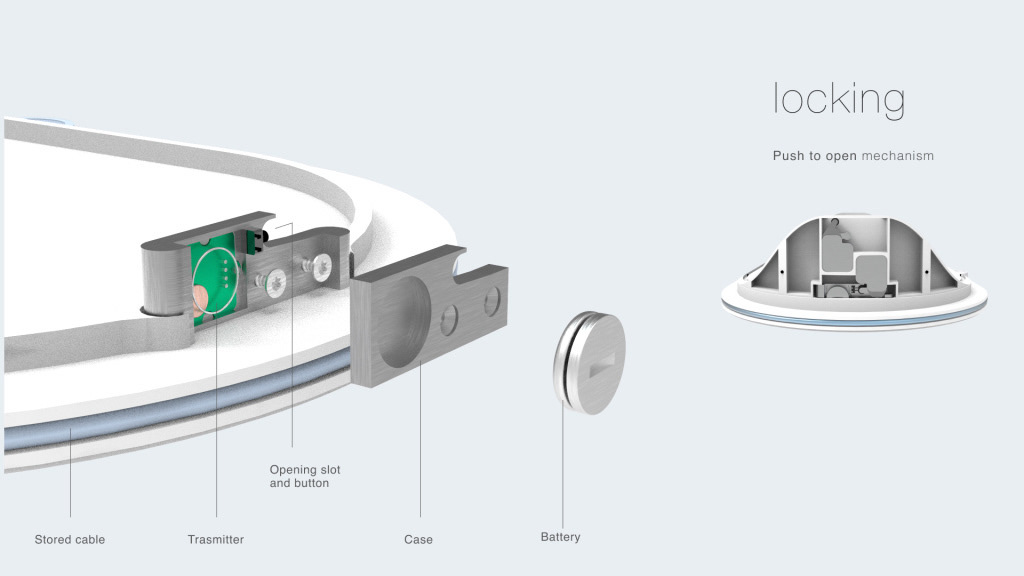

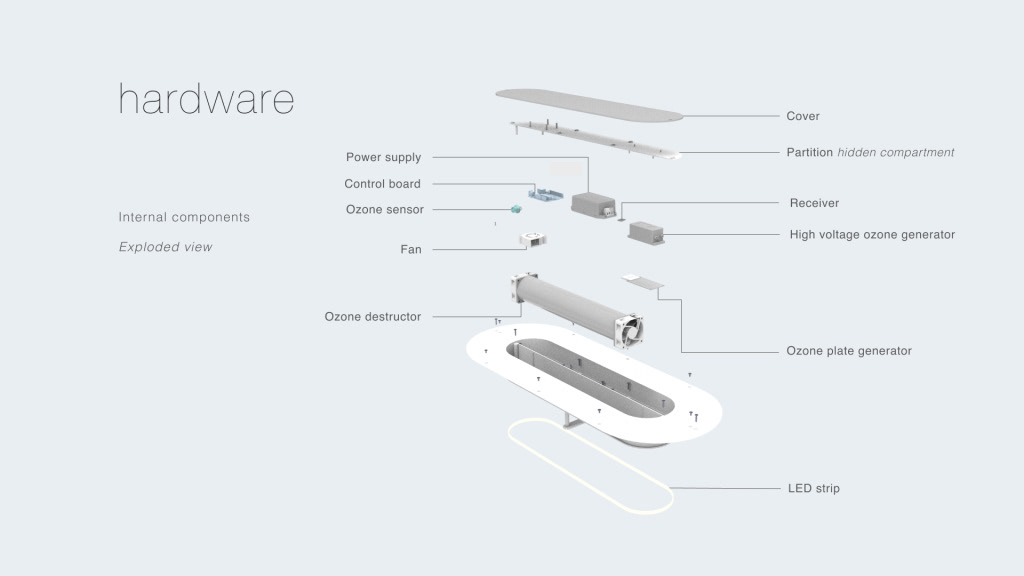

Aeriform uses mny standard components but also many parts designed and produced ad hoc. The philosophy behind this product was to make Aeriform mostly monomateric; to ensure its' circularity, ease of disassembly and recyclability. The bigger components are designed to be produced by injection moulding using polypropylene (PP). Parts are designed to be easily extracted from their molds. The foldable shell is a particular type of polypropylene called XPP which has features such as gas resistance and compression rate. Ozone if inhaled can be dangerous for your health, the safety of the system is imperative. We opted for a smart and simple mechanism which is commonly used, a push-to-open locking system. Additionally the ozone sensor presents another layer of safety.

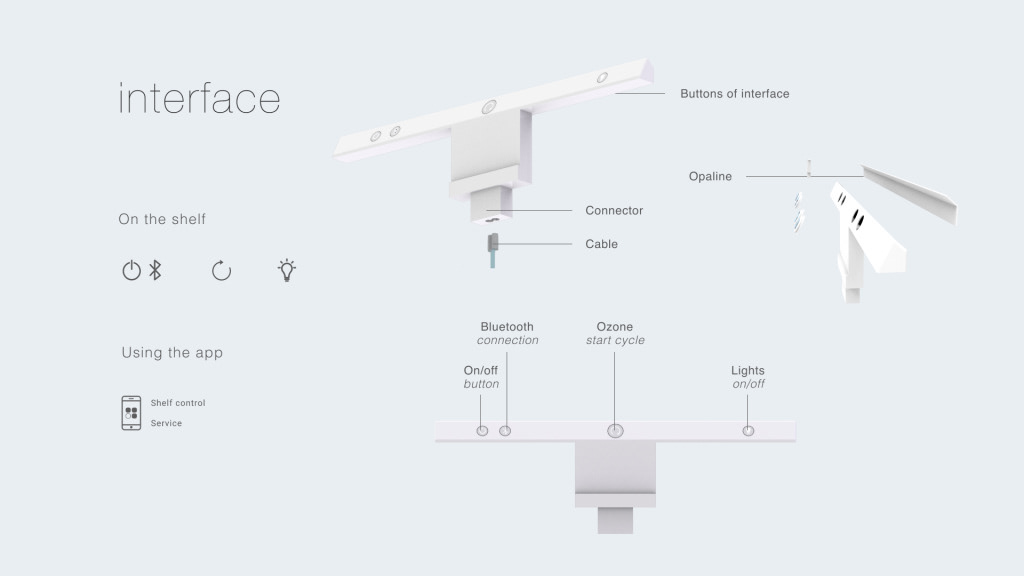

By scanning the QR printed on the packaging the user is redirected to the app where tutorials and tips to install the product can be easily found. When the installation phase is completed, the user can start setting up the Aeriform by following the instructions on the app. Through the app users are also able to see their environmental impact.

What are the steps that the user has to perform in order to sanitise clothes in the best way? The video storyboard visualises the prototype we made as well as the instagram filter we created to simulate the virtual trial.